Facility

Manufacturing Facility

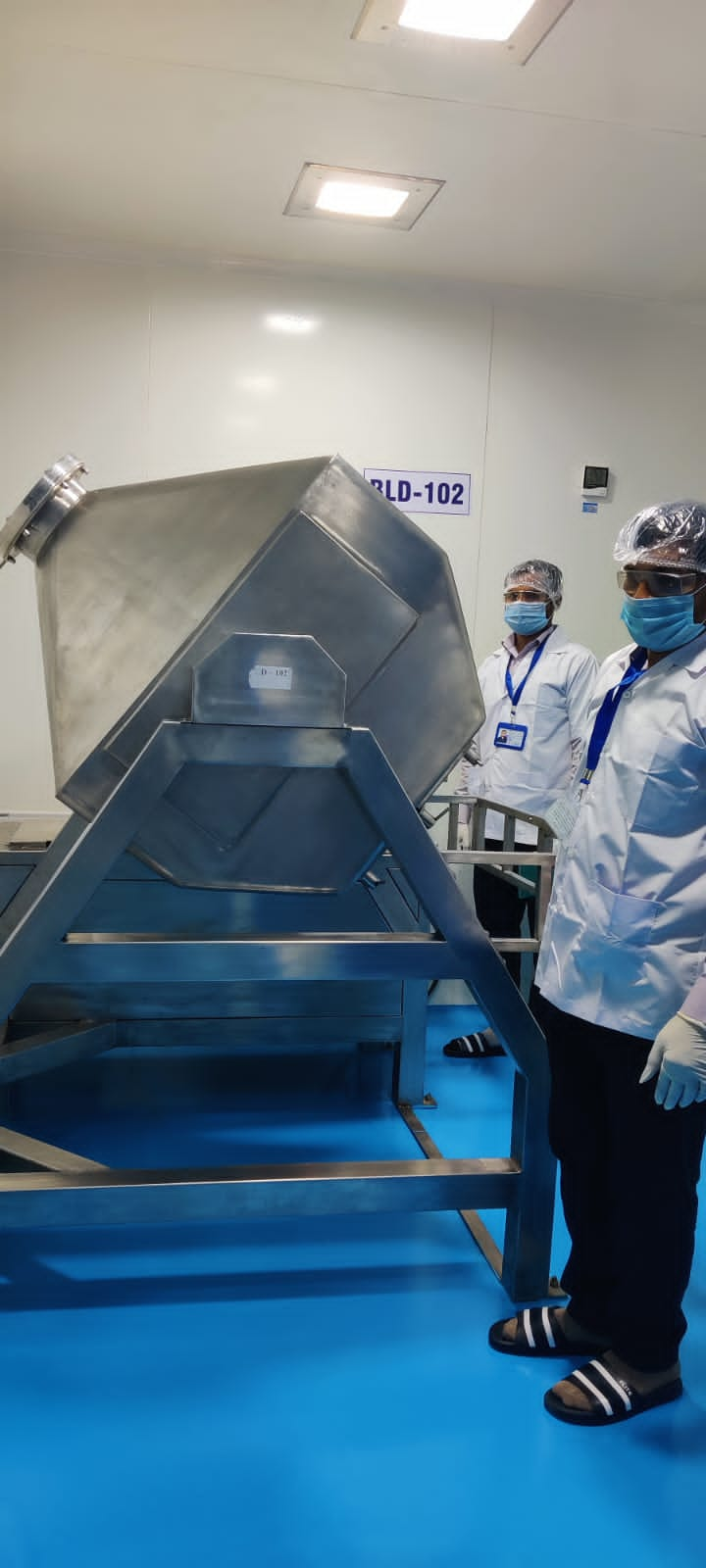

The manufacturing Plant of Paragon Organics is fully compliant with WHO cGMP guidelines and equipped with the advanced modern facilities and equipments. Our Global quality standards can be quantified by the various international accreditations that we have acquired. We are continually striving to improve our capabilities to meet the requirements of the customers.

We adopt the best practices in all our plant operations to ensure good quality products. Every team is highly skilled and experienced in its field. Our quality management system ensures the consistency of high standard products.

Quality Assurance Department

We have a well-established Quality Assurance Department in compliance with National and International regulatory requirements. The team members are highly qualified, professionally skilled and well-trained. The Quality Assurance team makes sure to maintain the consistent quality of products by following the guidelines of WHO, and ISO 9001:2015.

The regular internal audit conducted by Quality Assurance Department to ensure that an established process is followed by all functional departments, to find out GMP gap, if any, and scope of improvement.

We ensure manufacturing process delivers quality products consistently while meeting specifications as per established procedures and protocols, especially with respect to periodic re-validation, equipment qualification, annual product review and stage monitoring. All factors including, men, materials, machine, utility, facility and environment, which may affect the quality of the product are monitored.

Quality Control Department

The Quality Control Department gives highest emphasis to the superior quality for all products with its highly educated, well-trained, skilled and dynamic professionals. The team ensures the quality & safety remains an integral part of the entire cycle, starting from raw materials, to packaging.

Engineering Department

Engineering Department of the company takes care of all manufacturing activities by providing prompt support with utilities, breakdown repairs and preventive maintenance and use of qualification, requalification of all equipments involved in critical operations.

Warehouse – Raw material, packaging material, finished product storage

Ware house is available for the storage of Raw material, Packaging material and Finished product. It has separate sections for the receival, quarantine, sampling and dispensing. All these areas are strictly maintained under Closed-Circuit Surveillance. The status of materials and products are controlled by colored labels.

There is separate area for storage of rejected raw material, or rejected & returned finished products.